Initiating Devices: Heat Detectors, CO Detectors, Multi-Sensor Detectors

Daniel Torpey is Senior Systems Consultant at DGA Security and oversees all commercial fire system installations at DGA. He also currently serves as a member of the NYC Department of Buildings’ Fire Protection Systems Technical Committee, which assists with drafting revisions to the New York City Construction Codes. Dan’s previous industry experience includes serving on the test development committee with NICET (National Institute for Certification in Engineering Technologies) and serving as a member of the FDNY Certificate of Fitness Committee.

This article provides an overview of heat detectors, carbon monoxide (CO) detectors and multi-sensor detectors, which are all fire alarm initiating devices. We'll explain what they are, how they work and where they are used. In commercial fire alarm systems, initiating devices play a critical role of detecting an active fire and dangerous level of carbon monoxide as well as monitoring the sprinkler system to ensure that it's in proper working condition.

Heat detectors, as the name suggests, sense temperature rather than smoke. In comparison to smoke detectors, heat detectors can take much longer to reach an alarm threshold. Due to their longer reaction time, heat detectors aren’t considered life safety devices. Their primary role is to minimize property damage rather than to protect people. So why use heat detectors at all? Heat detectors are useful in environments that contain a lot of dust particles, smoke or steam that can cause false alarms for smoke detectors. For example, in commercial buildings, heat detectors are frequently used in boiler rooms and commercial kitchens where a lot of smoke and steam can be found during the normal day-to-day operations.

Heat detectors come in three varieties: rate-of-rise, fixed temperature, and a combination of rate-of-rise and fixed temperature.

Rate-of-rise heat detectors trigger an alarm signal when temperature rises rapidly, generally 12℉-15℉ per minute. A downside to rate-of-rise heat detectors is that they are slow to react to fires that develop slowly.

Fixed temperature heat detectors are calibrated to trigger an alarm signal when the surrounding environment reaches a specific temperature, typically 135℉. Fixed temperature heat detectors with a 170℉ setpoint are also available to use in locations that have a higher normal ambient temperature. One downside to fixed temperature heat detectors is a delayed reaction time from a fire that builds rapidly. When a fire builds quickly, the temperature rises too fast to be measured accurately by fixed temperature heat detectors. This “thermal lag” often causes fixed temperature heat detectors to trigger an alarm signal when the ambient temperature has exceeded the setpoint, which means the fire is much further advanced by the time it is detected.

Fixed temperature heat detectors are calibrated to trigger an alarm signal when the surrounding environment reaches a specific temperature, typically 135℉. Fixed temperature heat detectors with a 170℉ setpoint are also available to use in locations that have a higher normal ambient temperature. One downside to fixed temperature heat detectors is a delayed reaction time from a fire that builds rapidly. When a fire builds quickly, the temperature rises too fast to be measured accurately by fixed temperature heat detectors. This “thermal lag” often causes fixed temperature heat detectors to trigger an alarm signal when the ambient temperature has exceeded the setpoint, which means the fire is much further advanced by the time it is detected.

To address this thermal lag issue, newer multi-criteria heat detectors are designed to sense both the rate-of-rise and the fixed temperature setpoint. They operate like standard fixed temperature heat detectors but their rate-to-rise sensor counteracts the thermal lag if a fire were to build quickly.

To address this thermal lag issue, newer multi-criteria heat detectors are designed to sense both the rate-of-rise and the fixed temperature setpoint. They operate like standard fixed temperature heat detectors but their rate-to-rise sensor counteracts the thermal lag if a fire were to build quickly.

While the combination heat detectors are gaining more traction, fixed temperature heat detectors are still the most commonly used heat detectors you’ll see in buildings. When activated, heat detectors will transmit an alarm signal to the Fire Alarm Control Panel (FACP), which will alert the occupants to leave the premises using audible and visual alarm devices. The monitoring center will also receive the alarm signal and call the local fire department to dispatch emergency responders.

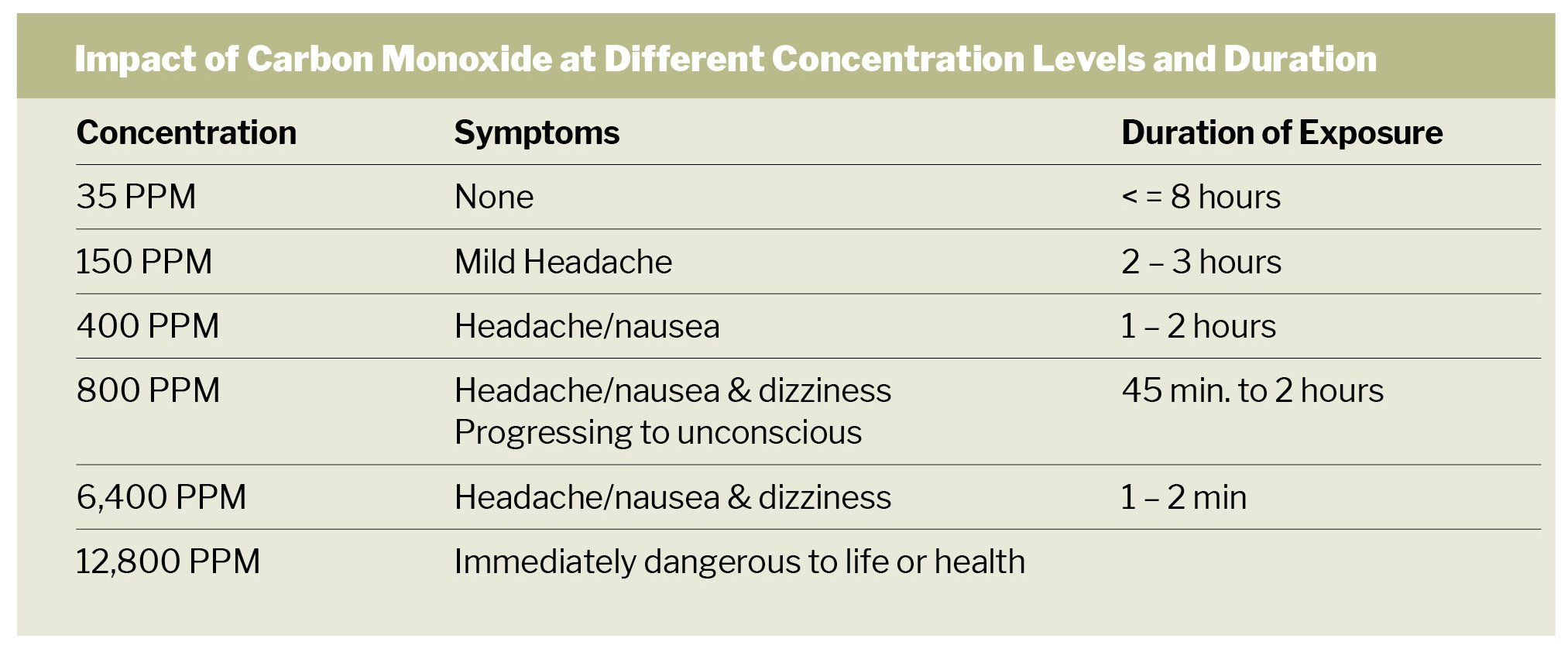

CO detectors monitor carbon monoxide levels. Carbon monoxide is called the “silent killer” because it’s odorless and colorless yet highly lethal. CO is produced during incomplete burning of carbon fuels (think running cars with gasoline engines, oil- or gas-based heating systems or generators). CO detectors operate by measuring the CO level, which is measured in parts-per-million (ppm), over a time period. The higher the ppm of the CO level, the shorter the allowed time period before an alarm is initiated. While where and how to install CO detectors for commercial buildings depends on local codes, CO detectors are typically required in hotel rooms, schools, rooms or floors that contain CO-producing equipment, and in indoor garages.

CO detectors monitor carbon monoxide levels. Carbon monoxide is called the “silent killer” because it’s odorless and colorless yet highly lethal. CO is produced during incomplete burning of carbon fuels (think running cars with gasoline engines, oil- or gas-based heating systems or generators). CO detectors operate by measuring the CO level, which is measured in parts-per-million (ppm), over a time period. The higher the ppm of the CO level, the shorter the allowed time period before an alarm is initiated. While where and how to install CO detectors for commercial buildings depends on local codes, CO detectors are typically required in hotel rooms, schools, rooms or floors that contain CO-producing equipment, and in indoor garages.

Source: Edwards

Similar to smoke and heat detectors, CO detectors transmit an alarm signal when activated and fire trucks will show up at the location. But an alarm signal from CO detectors doesn’t cause the FACP to activate the notification devices. Rather, CO detectors have a local sounder that emits a unique “temporal four” tone, meaning each tone cycle has four on-and-off sequences, followed by a five-second silent period, then repeats (hear the CO detector temporal four tone). Having a distinct CO alarm sound allows people in the affected area to differentiate it from the fire alarm sound and take appropriate actions, such as opening windows and evacuating the affected area.

Multi-sensor detectors, also called multi-criteria detectors, combine one or more fire detection technologies into a single device. By using multiple sensors — for smoke, heat and carbon monoxide — these devices can provide more accurate fire detection, reduce false alarms and simplify installation. While multi-sensor detectors come in all combinations, the combination we install the most is smoke and CO. This is because smoke and CO are useful in spaces that require both detectors, such as hotel rooms and schools.

Multi-sensor detectors, also called multi-criteria detectors, combine one or more fire detection technologies into a single device. By using multiple sensors — for smoke, heat and carbon monoxide — these devices can provide more accurate fire detection, reduce false alarms and simplify installation. While multi-sensor detectors come in all combinations, the combination we install the most is smoke and CO. This is because smoke and CO are useful in spaces that require both detectors, such as hotel rooms and schools.

To learn more about different fire alarm initiating devices, read these related articles:

Initiating Devices (Part 1) - Smoke Detectors, Duct Smoke Detectors and Multi-Sensor Detectors

Initiating Devices (Part 3) - Manual Pull Stations and Waterflow Switches

Initiating Devices (Part 4) - Supervisory Switches for Monitoring Automatic Fire Sprinkler Systems